I. Introduction

New materials refer to newly emerged materials with excellent performance and special functions, as well as materials with traditional material composition and improved technology that have significantly improved performance or new functions. The new materials industry, which incorporates the advanced achievements of many contemporary disciplines, is the basic industry supporting the development of the national economy and the material basis for the development of other high-tech industries.

Throughout history, new materials can lead to the emergence of disruptive technologies, thereby driving industrial change. For example, the emergence of white light-emitting diodes (WLED) opened up a new era of lighting; LCD screens replaced cathode camera tubes, which once brought a display revolution; now organic light-emitting diodes (OLED), printed displays, and laser displays will rise again, which have a generation of materials, have a generation of devices, one generation of machines. After years of hard work, my country’s new material industry has made important achievements, the technological level has been improved, the scale of the industry has been continuously expanded, and a new material industry system with independent innovation capabilities is being formed. It has served my country’s aerospace, rail transit, information, biological, and new energy industries. The representative high-tech industry has provided strong support for breaking through technological bottlenecks and achieving leapfrog development.

But on the whole, the competitiveness of my country's new materials industry still needs to be strengthened. The independent innovation system with enterprises as the main body needs to be improved urgently. Some core key materials are controlled by others, and the high-end materials are still highly dependent on foreign sources. For this reason, it is imperative to seize the opportunity, make reasonable plans, and improve the supporting capacity of the new material industry. This is of great strategic significance for accelerating the transformation of my country's economic development mode, enhancing the strength of the national defense industry, and achieving the goals of energy conservation and environmental protection.

2. The current status of foreign new material R&D and industrial development

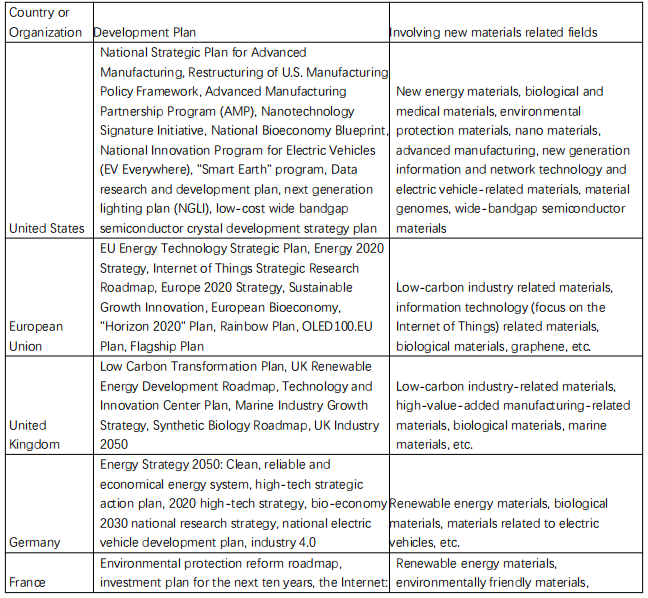

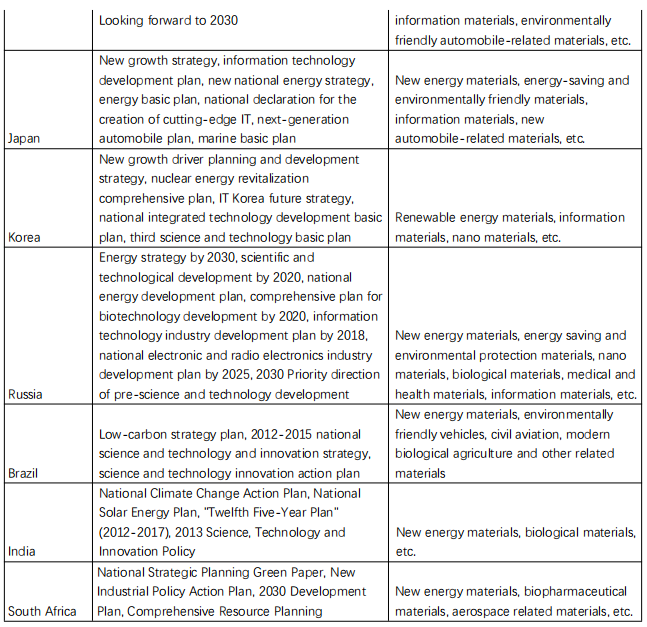

In recent years, countries around the world have formulated corresponding plans in the field of new materials (see Table 1), comprehensively strengthened R&D, and introduced policies at different levels such as the market and industrial environment. The United States issued the "National Innovation Strategy" three times in 2009, 2011 and 2015. Priority development areas such as clean energy, biotechnology, nanotechnology, space technology, and health care all involve new materials; the "Advanced Manufacturing Strategy" formulated in 2012 Industry National Strategic Plan" to further increase support for material technology innovation. In order to achieve economic recovery, eliminate development ailments, and cope with global challenges, the European Union formulated the "Europe 2020 Strategy" in 2010 and put forward three strategic priorities. The German government released "Creativity, Innovation, Prosperity: German High Technology 2020 Strategy", in which "Industry 4.0" is one of the most compelling topics among the ten future projects. In 2013, the United Kingdom launched "British Industry 2050", focusing on supporting the construction of innovation centers for new energy, smart systems, and materials chemistry. Japan issued the "New Growth Strategy" and "Information Technology Development Plan" in 2010. South Korea announced the "Green Growth National Strategy and Five-Year Action Plan" and "New Growth Driver Planning and Development Strategy" in 2009. Brazil, India, Russia and other emerging economies have adopted a key catch-up strategy, and formulated special plans in the fields of new energy materials, energy-saving and environmentally friendly materials, nanomaterials, biological materials, medical and health materials, and information materials, in an effort to seize the lead in future international competition A place.

In the context of increasingly accelerating globalization, the new material industry presents the following main characteristics and trends.

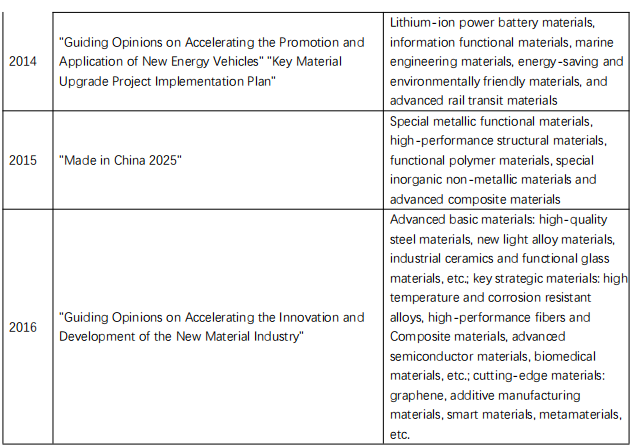

Table 1 Development plans in the field of new materials in countries around the world.

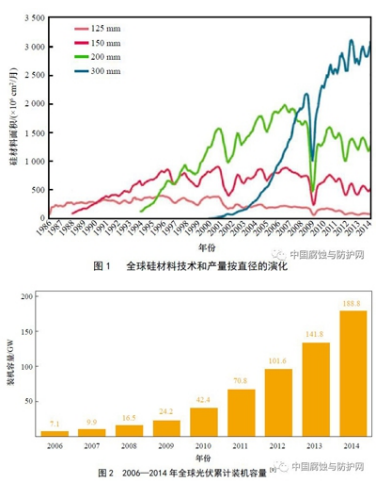

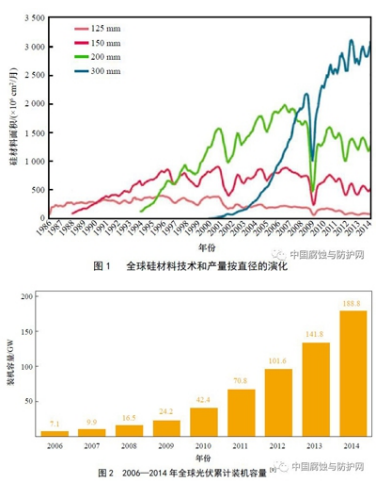

(1) The development of high-tech promotes the continuous updating of materials

The rapid development of high and new technology poses new challenges and demands for key basic materials, and at the same time, the upgrading of materials promotes the transformation of high-tech achievements into productivity. For example, the integration of microelectronic chips and the speed of information processing have greatly increased, and the cost has been continuously reduced. Silicon materials have played an important role. Currently, 300 mm silicon wafers can meet the integrated circuit requirements of the 14 nm technology node, and samples of 450 mm silicon wafers have been produced. Figure 1 shows the evolution of global silicon material technology and production by diameter. An important breakthrough has been made in the R&D of low-temperature co-fired ceramic technology (LTCC), and it has become possible to integrate a large number of passive electronic components on the same substrate. With the continuous expansion of advanced materials research technology, many emerging industries have also emerged. The development of compound semiconductor materials such as gallium nitride has given birth to semiconductor lighting technology; the luminous efficiency of white LEDs has far exceeded that of incandescent lamps and fluorescent lamps, bringing revolutionary changes to the lighting industry. The continuous improvement of solar cell conversion efficiency has greatly promoted the development of the new energy industry. Breakthroughs have been made in the processing technology of high-performance structural materials such as magnesium alloys and titanium alloys, and the costs have been continuously reduced. The development of clinical diagnostic materials and devices based on molecules and genes has enabled the early detection and treatment of major diseases such as liver cancer; the R&D of interventional devices has spawned minimally invasive and interventional treatment technologies, which have greatly reduced the mortality rate of heart disease and other diseases.

(2) Green and low carbon have become important trends in the development of new materials

The rise of emerging industries represented by new energy has caused major changes in many industries such as electricity, construction, automobiles, and communications, and stimulated the development of a series of manufacturing and resource processing industries such as wind turbine manufacturing, photovoltaic modules, polysilicon, etc. Development and production of transmission and terminal products such as smart grids and electric vehicles. Developed countries such as Europe and the United States have passed legislation to promote the development of energy-saving buildings and photovoltaic power generation buildings. At present, 80% of the insulating glass in Europe uses LOW-E glass, and the penetration rate of LOW-E insulating glass in the United States has reached 82%. The installed photovoltaic capacity is continuously increasing. Figure 2 is the cumulative installed capacity of global photovoltaics in recent years. It can reduce costs and improve quality by improving the strength and toughness of new structural materials, improving temperature adaptability, prolonging service life, and material composite design. For example, the compressive strength (CAI) of T800 carbon fiber reaches 350 MPa, and the use temperature reaches 400 ℃ or higher. It has been widely used in the main structural parts of aircraft and missiles. Functional materials are developing in the direction of miniaturization, multi-functionalization, module integration, and intelligence to improve the performance of materials; the fusion of nanotechnology and advanced manufacturing technology will produce smaller volumes, higher integration, more intelligent, and more functional Excellent product. Green, low-carbon new material technology and industrialization will become the main direction of future development. While pursuing economic goals, it will pay more attention to social goals such as resource conservation, environmental protection, and public health.

(3) Multinational groups still occupy a dominant position in the new materials industry

At present, world-renowned enterprise groups continue to expand into the field of new materials by virtue of their advantages in technology R&D, capital and talents, and occupy a leading position in high value-added new material products. Companies such as Shin-Etsu, SUMCO, Siltronic, and SunEdison account for more than 80% of the international semiconductor silicon material market. More than 90% of the semi-insulating gallium arsenide market is occupied by Japan's Hitachi Electric, Sumitomo Electric, Mitsubishi Chemical and German FCM. Dow Chemical Company, GE Company, Wacker Company, Rhone-Poulenc Company and some Japanese companies basically control the global silicone material market. Seven companies including Du Pont, Daikin, Hoechst, 3M, Ausimont, ATO and ICI have 90% of the world's organic fluorine material production capacity. The silicon carbide substrate preparation technology of American Cree Company has strong market competitiveness. The power white LED of American Lumileds Company, which is controlled by Philips, is the world leader. American, Japanese, German and other countries have 70% LED. Core patents for epitaxial growth and chip preparation. The manufacture of small tow carbon fiber is basically monopolized by Japan’s Toray Fiber Corporation, Toho Corporation, Mitsubishi Corporation and Hexel Corporation of the United States, while the large tow carbon fiber market is almost dominated by Fortafil Corporation, Zoltek Corporation, Aldila Corporation and the United States. Four SGL companies in Germany are occupied. Alcoa, Deutsche Aluminium, French Alcoa and other world-leading companies occupy a leading position in the world in the development and production of high-strength and high-toughness aluminum alloy materials. The three major titanium producers in the United States, Timet, RMI and Allegen Teledyne, account for 90% of the total titanium processing in the United States, and are the world's major suppliers of aviation-grade titanium materials.

(4) The reform of new material R&D model has become the focus of attention

Since the beginning of the 21st century, developed countries have gradually realized that traditional materials research methods that rely on trial and error can no longer keep up with the rapid development of industry, and may even become a bottleneck restricting technological progress. Therefore, there is an urgent need to innovate materials R&D methods and accelerate the process of materials from R&D to application. For example, as an important part of the US government's "Advanced Manufacturing Partnership Program" (AMP), the "Material Genome Program" (MGI) launched in 2011 has at least doubled the speed of new materials from discovery to application, and reduced costs by at least half , Aims to develop high-end manufacturing based on advanced materials and continue to maintain its advantages in the core technology field. The material genome elements are shown in Figure 3. The specific contents of MGI include: ①Develop high-throughput calculation tools and methods, reduce time-consuming and laborious experiments, and speed up material design; ②Develop and promote high-throughput material preparation and testing tools, and perform candidate material verification and screening faster; ③Develop and improve material database/informatics tools, and effectively manage the data chain from discovery to application; ④Cultivate open and collaborative new cooperation models.

In this process of changing the material R&D model, the European Union and Japan have also launched similar scientific programs. For example, the European Union has launched the "Accelerated Metallurgy" (ACCMET) program driven by the demand for six types of high-performance materials, including light weight, high temperature, high temperature superconductivity, magnetism and thermomagnetic, thermoelectric and phase change memory storage.

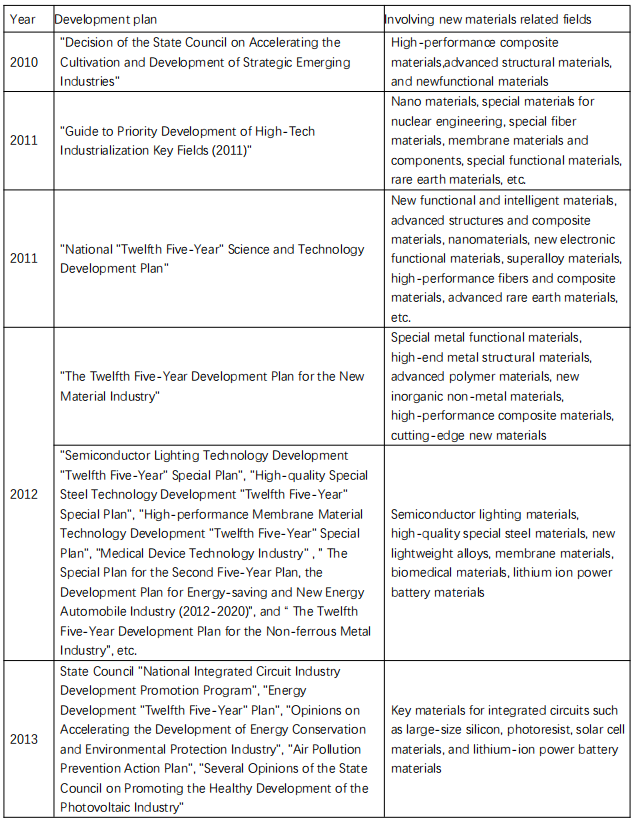

3. Current status of my country's new material R&D and industrial development

Since the "Twelfth Five-Year Plan", the Chinese government has attached great importance to the development of the new material industry. Following the "Twelfth Five-Year" National Strategic Emerging Industry Development Plan and the "Twelfth Five-Year Development Plan of the New Material Industry" and other national-level strategies With the introduction of the plan, the Ministry of Industry and Information Technology, the Development and Reform Commission and other relevant ministries and commissions have successively issued relevant development plans for the new materials industry and other strategic emerging industries (see Table 2). The Ministry of Science and Technology has issued special plans for related technological development, including green manufacturing technology development, semiconductor lighting technology development, green building technology development, clean coal technology technology development, seawater desalination technology development, new display technology development, national broadband network technology development, China Cloud Scientific and technological development, medical technology development, service robot technology development, high-speed train technology development, manufacturing informatization, solar energy technology development, wind power generation, smart grid major technology industrialization projects, etc., all include the development and application of new materials.

Table 2 my country's development plans related to the new material industry

(1) The scale of the new material industry continues to expand

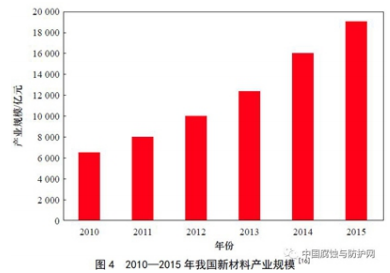

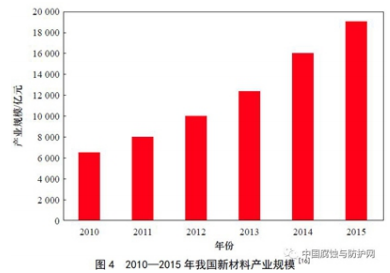

In 2015, the scale of my country's new materials industry was about 1.9 trillion yuan. The industrial production capacity of rare earth functional materials, advanced energy storage materials, photovoltaic materials, superhard materials, special stainless steel, glass fiber and its composite materials ranks among the top in the world. In 2015, solar cell modules reached 23 GW, an increase of 20.8% year-on-year; the semiconductor lighting industry has initially formed a relatively complete R&D and industrial system from upstream epitaxial material growth and chip manufacturing, midstream device packaging to downstream integrated applications. In 2015, the industrial scale exceeded 500 billion yuan. In 2014, the output of semiconductor silicon materials in China reached 400 million in2 (1 in2=6.451 6 cm2), accounting for about 4% of the global share, an increase of 23% compared to 2010; the float glass production line for low-emission and solar control energy-saving glass has exceeded 20 There are more than 150 offline magnetron sputtering energy-saving glass production lines, and the energy-saving glass material industry scale has reached 30 billion yuan; the output of rare earth functional materials such as rare earth magnetic materials, rare earth luminescent materials, and rare earth hydrogen storage materials accounts for about 80% of the global share ; The industrial scale of main functional ceramic components has increased to 25.1 billion yuan. Figure 4 shows the scale of China's new materials industry from 2010 to 2015.

(2) The research level of new materials is further improved

Since the beginning of the new century, through the combination of production, education, research and application, substantial breakthroughs have been made in a number of core key technologies, the technical indicators of many important new materials have been greatly improved, and some research results have been promoted and applied in related fields. Large-diameter silicon materials continue to improve in terms of control technologies such as defects, geometric parameters, particles, and impurities. 300 mm silicon materials can meet the requirements of integrated circuits at the 45 nm technology node, and 450 mm silicon single crystals have been successfully drawn. After years of development of intraocular lens materials, the research on UV nonlinear optical crystals such as barium metaborate (BBO) and lithium triborate (LBO) ranks internationally and has achieved commercialization; potassium fluoroborate beryllate (KBBF) crystals are internationally The only practical deep-ultraviolet non-linear optical crystal, and the first successful preparation of advanced scientific instruments in my country; the main technical indicators of laser crystals such as Nd:YAG, Nd:GGG and Nd:YVO4 have reached the international advanced level, achieving kilowatt-level all-solid-state Laser output. The key technical indicators of solar cells have reached the international advanced level, and the cost of photovoltaic power generation has fallen below 1 yuan/(kW · h). Lithium-ion battery cathode materials, anode materials, and electrolytes can all meet the requirements of small batteries, and key materials such as diaphragms and electrolyte lithium salts have basically changed the situation of relying on imports. Through the industrial development of technologies such as ultra-high molecular weight polyethylene fiber, halogenated butyl rubber, and high-performance oil-displacing polymers, the gap between my country's chemical materials industry and developed countries has been greatly reduced. T300-grade carbon fiber has achieved stable production, and the single-line production capacity has been increased to 1 200 tons; T700 and T800-grade carbon fibers have achieved breakthroughs in key technologies, achieved mass supply capabilities, and have begun to be used in aerospace equipment. Developed a rapid solidification spray-deposited aluminum alloy with a strength greater than 800 MPa and a new generation of high-strength, high-toughness and high-hardenability aluminum alloys, with comprehensive performance reaching the international advanced level; developed copper strip, copper tube drawing and casting technology with independent intellectual property rights and copper Aluminum composite technology. The performance of sub-micron ultra-fine-grained cemented carbide monolithic tools has reached the world's advanced level. Submarine pipeline steel X65, X70, X80, thick-walled marine oil and gas welded pipes, and medium and thick plates for chemical tankers have all been domestically produced. The independently developed 2205 duplex stainless steel has been successfully applied to chemical tankers. The continuous breakthroughs in key technologies and the continuous increase in the variety of new materials have significantly strengthened my country's high-end metal structural materials, new inorganic non-metallic materials, and high-performance composite materials, and the self-sufficiency of advanced polymer materials and special metal functional materials has gradually increased. The national standard "Terms of Electromagnetic Metamaterials" was released, and the new satellite communication products developed based on metamaterials and radio frequency technology won the Innovation Gold Award of the first China Electronic Information Expo. Low-cost graphene has been produced and applied to information communication devices such as touch screens and thermal conductive films.

(3) The regional agglomeration trend of new materials industry is obvious

In recent years, governments have actively promoted the construction of new material industry bases, strengthened resource integration, and presented a good trend of agglomeration development. Regional characteristics have gradually emerged, and a spatial pattern of "agglomeration of eastern coastal areas and characteristic development of central and western regions" has initially formed. The Yangtze River Delta has a solid industrial foundation, convenient transportation and logistics, and complete industrial facilities. It has formed a new material industry cluster in aerospace, new energy, electronic information, and new chemical industries. The economy of the Pearl River Delta is mainly export-oriented, and high concentration of new materials industry, and the downstream industries are obviously driven. A relatively complete industrial chain has been formed. It has strong capabilities in the fields of electronic information materials, modified engineering plastics, and ceramic materials. The Bohai Rim region has an obvious role in promoting technological innovation, and has strong regional scientific and technological support capabilities. It has great advantages in multiple new materials such as rare earth functional materials, membrane materials, silicon materials, high-tech ceramics, magnetic materials and special fibers. New rare earth materials in Inner Mongolia, new rare and precious metal materials in Yunnan and Guizhou, new non-ferrous materials in Guangxi, neodymium iron boron permanent magnet materials in Ningbo, new chemical materials industries in Guangzhou, Tianjin, Qingdao and other places, Chongqing, Xi’an, and Jinchang in Gansu Aerospace materials, energy materials, and major equipment materials in Changzhutan, Hunan, Baoji, Shaanxi, Weihai, Shandong and Taiyuan, and polysilicon materials industries in Xuzhou, Jiangsu, Luoyang, Henan, and Lianyungang, Jiangsu have also formed their own regional characteristics.

(4) The role of new materials supporting major application demonstration projects has become increasingly apparent

The new material industry provides important technical support for the development of my country's energy, resources, environment, and information fields, and is an important guarantee for the construction of major projects and the consolidation of the national defense industry. Governments at all levels organized and implemented major application demonstration projects such as energy-saving products benefiting the people, ten cities million, Golden Sun, and the Internet of Things, and promoted more than 30 million energy-saving air conditioners, more than 3.6 million energy-saving vehicles, and high-efficiency energy-saving motors 4×106 kW , 160 million energy-saving lamps, more than 1.6 million LED lights; construction of more than 340 photovoltaic power generation projects; through the support of demonstration projects such as ten cities and 1,000 vehicles and related policies, the output of new energy vehicles in China in 2015 reached 379,000, ranking the world First, it is expected that China's new energy vehicle market will reach 5 million in 2020, and it is expected to reach 15 million in 2030. Membrane materials have been applied in seawater desalination, and the production capacity of reverse osmosis seawater desalination has initially formed, and it has become an important part of the water supply security system in coastal areas of my country. High-performance structural materials represented by new non-ferrous metal structural materials, special steel materials, refractory metals, high-temperature alloys, carbon fiber and their composite materials are key materials that are indispensable for the development of today’s high technology. The smooth implementation of major projects such as aerospace, lunar exploration projects, ultra-high voltage power transmission, and deep-sea oil and gas development have made contributions.