4. Trends and characteristics of the development of new materials industry

The development of new materials presents the characteristics of integration of structure and function, integration of materials and devices, nanometer, composite, and green. Its role is to play in high Mach number aircraft, micro-nano electromechanical systems, new medicines, advanced cosmetics and new energy batteries It's so vivid.

New materials play an important role in the technological progress of the industry. For example, high-performance special steels and high-temperature alloys are the best choices for high-speed rail wheels and aircraft engines, ultra-high-strength aluminum alloys are the key structural materials for large aircraft frames, and high-strength, high-toughness and corrosion-resistant titanium alloys are used for the Jiaolong shell and marine engineering. Indispensable material.

The combination of new materials or deep integration with other disciplines and fields has become another characteristic of its development. The combination of high-k and higher-k materials and new metal gates leads integrated circuits to smoothly move toward technology nodes of 45 nm and below. The combined use of perovskite materials and organic materials has given birth to promising new solar cells. The combination of smart materials and 3D printing forms 4D printing technology. The combination of organic composite materials, bioactive materials and clinical medicine produced and developed "electronic skin" and tissue regeneration engineering respectively. Carbon fiber and composite materials have been used in aerospace and advanced vehicles. Compound semiconductor materials enable terahertz technology to be applied in environmental monitoring, medical treatment, and anti-terrorism. Metamaterials combine microstructures and advanced materials to achieve remarkable results in the fields of electromagnetic waves and optics. The market prospects for flexible electronics materials, new energy materials, and biomedical materials are broad. Research on spintronics materials, iron-based and new superconducting materials is in the ascendant. Resistance change, phase change and magnetic storage materials will change the traditional semiconductor memory. Fullerene, graphene, and carbon nanotubes have opened up the development prospects of carbon-based materials; the successful exfoliation of graphene has triggered a research boom in two-dimensional materials such as molybdenum disulfide, single-layer tin, black phosphorus, silylene, germanene, etc. .

High-throughput calculations, high-throughput synthesis and characterization, and large-scale databases accelerate the design of new materials, performance predictions and preparation process simulations, greatly shorten the research and development cycle, reduce production costs, and provide a revolutionary way for the development and industrialization of new materials. Low-rhenium superalloys and new electrode materials for lithium-ion batteries are good examples. Recently, in topological insulator materials, the quantum anomalous Hall phenomenon predicted by calculation has been experimentally confirmed.

The R&D and production of new materials attach importance to energy conservation, environmental protection and renewability, and conduct full life cycle evaluation. Such as the substitution of toxic materials, the reduced use of medium and heavy rare earths, the use of membrane materials for seawater desalination, the application of building energy-saving materials, the development of bio-based materials, and the implementation of the concept of "short, small, light and thin". At the same time, low-carbon and environmentally friendly preparation technology has also been rapidly developed.

Focusing on military-civilian integration and opening up the market for dual-use products are the development trend of new materials. Wide band gap silicon carbide, gallium nitride-based next-generation radio frequency high-energy-efficiency and high-power devices are about to become high-end electronic products with potential military-civilian integration.

In addition, new methods, new processes, and new equipment for the preparation of new materials are essential and must be developed in a coordinated manner. The research results of new materials are rapidly industrializing and continuously reducing costs. The R&D, engineering and industrialization of new materials have become the focus of attention and focus of research units, universities, enterprises, governments and markets in various countries.

5. Problems in the development of my country's new materials industry

Since the reform and opening up, my country’s new materials industry has made considerable progress, the scale of the industry has continued to expand, and the level of industrial technology has been continuously improved. It has been at the international leading level in certain fields. The layout of industrial clusters has been accelerated, and the macro-development environment has been actively improved. The development has laid a solid foundation. New materials have become one of the four pillars of my country’s “industrial strength”. At the same time, “Made in China 2025” is also in urgent need of a large number of new materials. But on the whole, there is still a big gap between my country’s new material industry and the world’s advanced level, and there are still some prominent contradictions and problems in the development process. This has become a bottleneck restricting the rapid development of the new material industry, which is mainly reflected in the following four aspect.

(1) Insufficient top-level design and overall coordination, and low-level redundant construction

Judging from the current new material industry plans released by various regions in China, the top-level design of related industries is insufficient, and there is no reasonable positioning and differentiated division of labor based on its own conditions and advantages, and there is a serious convergence phenomenon. In some industries, products from the upstream of the industrial chain cannot be used in the downstream, resulting in overcapacity in the upstream and insufficient supply in the downstream market. In addition, blindly following the trend of investment has not been effectively curbed, and the result will not only cause redundant construction and overcapacity, but also affect the sustainability of industrial development.

(2) Insufficient original innovation capabilities, weak research and development and support capabilities for common technologies, and low self-sufficiency rate for high-end products

The original innovation ability of new materials in our country is insufficient, and there is a lack of in-depth communication and original theoretical research between different disciplines. As the main body of innovation, enterprises have less participation in innovation and R&D and more production tracking and imitation. There are generally low self-sufficiency rates of key technologies, few invention patents, and key components and core components are controlled by others. The common key technology of the industry is the basis for improving the capability of independent innovation. At present, most industries in my country do not have specialized industry generic technology R&D institutions, and generic technology R&D are in a state of lack; due to the lack of a good resource allocation mechanism and continuous effective investment, independent innovation cannot be supported at the source of technology. In addition, my country’s new materials have not formed a large number of material grades and systems with independent intellectual property rights; the national and industry standards, unified design specifications and material process quality control specifications for common basic raw materials are not perfect; there is a lack of new material structure designs that meet industry standards —Manufacturing-evaluation shared database, lack of basic support system. Most enterprises are still struggling in the vicious circle of "introduction-processing production-re-introduction-reprocessing production", which makes "Made in China" products lack of "created in China" elements and can only rely on cheap sales and low-level competition to find a way out. To a large extent, it has restricted the leapfrog development of the new material industry.

(3) Investment in new materials is scattered, and the industrial chain is not complete

At present, the industrial structure of some new materials in my country is not reasonable enough. The investment in the new materials industry supports some "points", and the linkage effect of dots with lines and lines with planes has not yet formed. The state is more willing to invest support funds in state-owned enterprises and scientific research institutes. Although private enterprises are encouraged to participate in competition in terms of policies, from an operational perspective, there are many barriers for private enterprises to enter the country's large-scale projects. In addition, the new material companies that are the main body of development are generally small in scale, lack of overall planning for industrial development, scattered investment, low rate of achievement conversion, and incomplete industrial chain. In some industries, most of the new material companies are concentrated in the middle and lower reaches, and the industrial supporting capacity is not strong.

(4) Policies and guarantee mechanisms are difficult to meet the requirements of the development of new materials industry

In the key links and key areas of the new materials industry, there is a phenomenon of "old methods governing new things", and it is difficult for innovative products to enter the market. Long administrative approval cycles (such as medical products) hinder the enthusiasm of enterprises to innovate. For projects with higher development risks, there is a lack of support from the funding guarantee mechanism. The market access mechanism also has certain defects. In addition, the new material industry service platform has not yet been established, and venture capital and intermediary services cannot meet the needs of enterprises for innovation and entrepreneurship. The transformation and engineering of new materials requires a lot of investment, but the diversified investment and financing system and intermediary service system for engineering services are not perfect, which restricts the innovation of new materials and the development of the industry.

6. Key directions for the cultivation and development of my country's new material industry

Facing the critical opportunity period when the new round of world scientific and technological revolution and industrial reform meet the transformation and upgrading of my country’s economic and social development mode, it is necessary to accelerate major technological breakthroughs in new materials, attach importance to innovation and application of disruptive and alternative technologies, and select to support the economy and social development and major needs of the defense industry are to create an environment suitable for industrial development, promote the upgrading of industrial structure, form a good industrial ecology, and promote sustainable economic and social development.

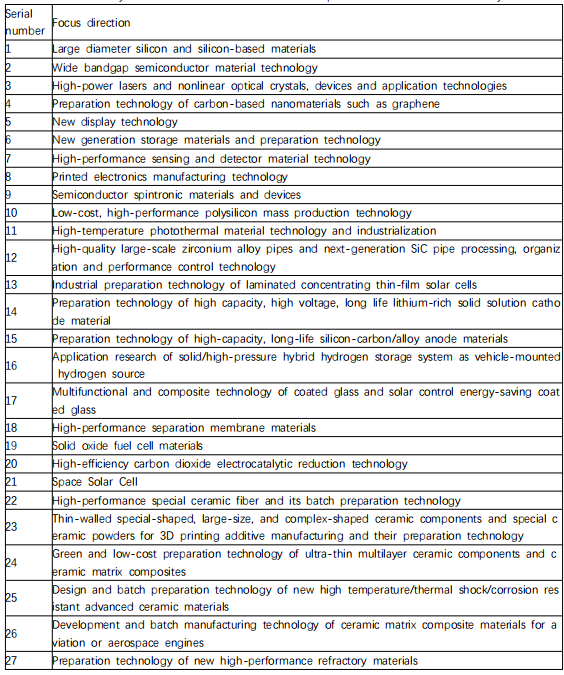

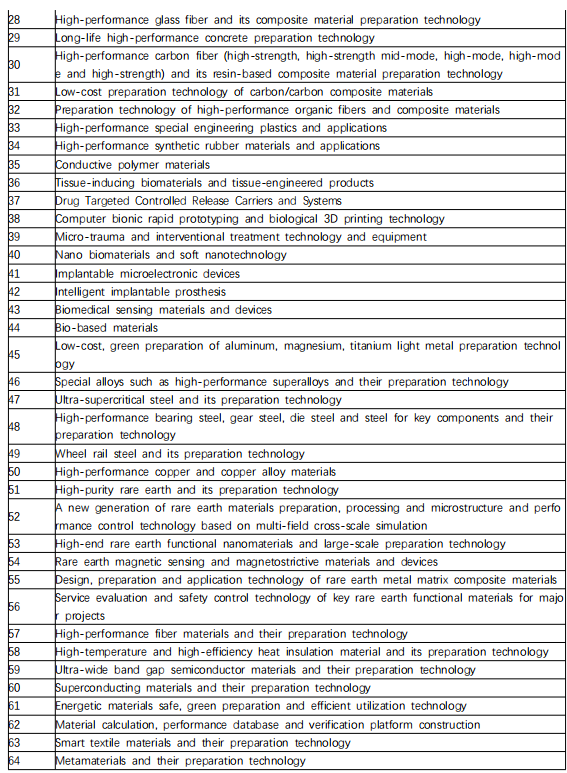

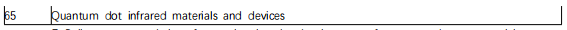

Table 3 lists the key directions and technologies for the cultivation and development of the new material industry that have been voted by experts. In the process of cultivation and development, we must pay more attention to improving product quality, promote the transformation of development mode to quality and efficiency, and enhance core competitiveness; we must pay more attention to the development of new resource-based materials and integrate them with ecological protection; The coordinated development of a new generation of information technology, new energy and environment, biology and health, and smart manufacturing in key national areas provides new material support for the realization of innovation-driven development strategies; more attention should be paid to the entire chain of materials from R&D, design, production to application The systematic development of the system enhances the ability of sustainable development; more attention should be paid to the energy consumption and cost of the new material industry, and a resource-saving and environment-friendly technical system, production system and benefit system should be established to achieve green, coordinated and sustainable development.

Table 3 Key directions for the cultivation and development of the new material industry

7. Policy recommendations for accelerating the development of my country's new material industry

Facing the needs of information, high-end equipment and manufacturing, green and low-carbon, biological and digital creative industries, and major projects, the quality and efficiency of the new material industry should be strengthened and the collaborative application should be strengthened to improve the basic support capabilities of new materials and promote the integration of new materials into the world high-end manufacturing supply chain. At the same time, further increase the self-sufficiency rate of major key new materials, deploy cutting-edge new material R&D, form a batch of forward-looking innovations, and speed up the realization of my country's transformation from a material country to a material power. The following suggestions are made.

(1) Strengthen top-level design and improve industrial policies

Strengthen the state's investment in basic research on new materials, attach great importance to cutting-edge new materials currently in the research and development stage, and make appropriate advance arrangements. Efforts will be made to break through the engineering problems of the development of the new material industry and improve the basic support capabilities of new materials. Accelerate the improvement of policies and legal systems that are conducive to the advancement of the new material industry, formulate a new material industry development guidance catalog and investment guide, establish a related technical standard system, and improve the industrial chain, innovation chain, and capital chain. Follow the principle of "who invests, who is responsible", strengthen the supervision of the return on state-owned capital investment; highlight the state's focused support for key industries, prevent "investment fragmentation", and concentrate on cultivating and shaping my country's famous brand new material products.

(2) Give full play to the role of the market in resource allocation, and build a development system with enterprises as the main body

On the basis of paying attention to the government's guiding role in the development of new materials industry, we will accelerate the creation of a market environment in which new materials-related companies operate independently and fair competition, with enterprises as the main body of investment and application of results, strengthen the combination of production, study and research, and give full play to the market The basic role of resource allocation is to improve the efficiency and fairness of resource allocation. Promote the implementation of strong alliances, cross-regional mergers and reorganizations, overseas mergers and acquisitions and investment cooperation by superior enterprises, increase industrial concentration, and accelerate the cultivation of internationally competitive enterprise groups. Seize the historical opportunity of accelerating the process of my country’s industrialization, cultivate and expand the consumer market for new materials, especially the mid-to-high-end market, drive development with demand, promote the upgrading of enterprises to grade and scale, promote supply-side structural reforms, and expand cooperation with international manufacturing enterprises. All-round cooperation to promote the rapid integration of new materials into the global high-end manufacturing supply chain.

(3) Strengthen the construction of support system and consolidate the foundation for development

Further increase the research and development support for new material preparation and testing automation equipment, concentrate on the development of core equipment to improve product quality and reduce manufacturing costs, pay attention to the development of new low-cost manufacturing processes and supporting technologies, and deepen the development of intelligent manufacturing of new materials technology. Build a research and development platform for material design and performance prediction under extreme conditions, formulate an index system for material service performance and lifetime cost, and comprehensively improve the level of material application in my country. Establish a new material structure design-manufacture-evaluation shared database, and use the downstream applications to build a material standard system that is in line with international standards and has Chinese characteristics. Strategically attach importance to and study the intellectual property system of the new material industry, strengthen intellectual property protection, encourage original innovation and integrated innovation in the research and development of new materials [28], gradually form material grades and systems with independent intellectual property rights, and carry out collaborative application pilots Demonstrate, build a collaborative application platform, and promote the structural adjustment and upgrading of the new material industry.

(4) Strengthen personnel training and actively introduce innovative talents

Implement the development strategy of innovative talents, support enterprises to strengthen the construction of innovative capabilities, continuously increase the training of innovative talents in the field of new materials, absorb high-level technical and managerial talents from abroad, and establish incentive and competition mechanisms suitable for the development of innovative talents. At the same time, new materials companies are encouraged to actively carry out international cooperation and exchanges, introduce foreign advanced technology and management experience, and continuously improve the management level of my country's new materials companies. Give full play to the role of industry associations, scientific research units and universities, jointly establish a new material expert system, and strengthen direct communication and exchanges in the development, production and application of new materials. The expert system regularly conducts investigations and assessments on the development and application requirements of new materials at home and abroad, plays the role of a think tank, and provides advice on the development of new materials and key issues that need attention.